The unique CALIPRI principle is a development of laser light section technology for non-contact dimension and profile measurements. It involves an

The unique CALIPRI principle is a development of laser light section technology for non-contact dimension and profile measurements. It involves an

Smartec SA was founded in 1996, as a result of the development our SOFO monitoring system at the Swiss Federal Institute of Technology – Lausanne

As a professional manufacturer of scientific glassware, DIMA GLASS offer an extensive line of laboratory glassware supplies for the needs of scientific

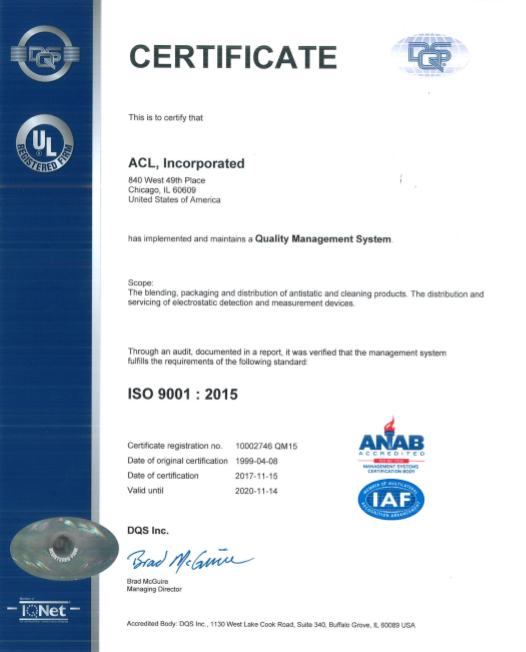

As testimony to ACL’s dedication to providing first-class products and services, we achieved ISO certification for our quality management system in

At INO, we specialize in developing solutions designed to make businesses more competitive, no matter what their size or area of activity. From consultation to production, we offer fast lead times and share the risks associated with technology development.

![]()

Smartec SA was Founded In 1996, As A Result Of The Development Our SOFO Monitoring System At The Swiss Federal Institute Of Technology – Lausanne (EPFL) Which Received Awards For Innovation At The Time. Today, Smartec Is A Leading Supplier Of Fiber-Optic Technology Used By The World-Wide Structural, Geotechnical, Energy And Oil & Gas Industry. We Employ Dedicated Individuals Who Focus On Providing Our Customers With The Best Solution To Their Technical Challenges.

(SHM) allows rapid assessment of a tunnel’s state of health and is recognized as one of the best ways to increase safety and optimize the operational and maintenance activities of tunnels.SHM plays an important role in every stage of tunnel construction, from the design stage for site evaluation, then during the construction stage to evaluate the impact of a project on nearby structures, and finally at the service stage to ensure the safety over its lifespan.

SBENEFITS OF OUR INTEGRATED HEALTH MONITORING SOLUTIONS AND LEAK DETECTION SYSTEMS Integrated solutions. Providing integrated structural health monitoring solutions for cyrogenic structures using advanced optic and fiber-optic technologies Access data on structure behavior.

Structural Health Monitoring (SHM)rapid assessment of a bridge’s health and is recognized as one of the best ways to increase general safety and optimize bridge operation and maintenance activities.

Monitoring nuclear power plants and nuclear waste storage sites present unique challenges that Roctest has successfully contributed to for decades.

The management of a geotechnical project requires a wide range of information gathered from sensors. This information is of vital importance for the correctbexecution of construction plans and refinement of soil models. With this system has been achieved the integration, standardization and high-level cooperation among all stakeholders.

Pipeline management presents challenges that are quite unique. Their long length, high value, high risk and often difficult access conditions require continuous monitoring and optimizing maintenance interventions. The main concern for pipeline owners involves leaks that if not detected can severely impact the environment or render the pipeline out of service.

As testimony to ACL’s dedication to providing first-class products and services, we achieved ISO certification for our quality management system in February 1995. It is our policy to achieve the highest standards of product quality and customer service. In order to achieve this, the company has implemented a corporate wide quality system in accordance with ISO 9001:2008. The quality system communicates expectations, establishes controls and fosters a culture committed to excellence in everything we do with a focus on continual improvement. Through management leadership, internal communication, competence, awareness and training, we are committed to meeting the objectives of the company to achieve the highest standard of product quality and service.

Proven effective after years of use in industrial, commercial and institutional facilities, Staticide® has become a trusted name in static protection and the closest thing there is to "static control insurance". Anti-static topicals are easy-to-use solutions that reduce static electricity. Staticide® anti-stats decay static to a zero charge faster than any other anti-static topical on the market. Unlike other anti-static topicals, Staticide® Concentrate is formulated to be effective independent of relative humidity.

Staticide®, the original anti-static concentrate, is the key ingredient in many ACL anti-static solutions. Once diluted with water or isopropyl alcohol, it eliminates a host of static control problems - especially in the electronics, textiles and plastics industries. Staticide® Concentrate saves freight, handling and storage costs for high production facilities while offering greater flexibility in dilution.

ACL's family of anti-static coatings for plastics provides dependable protection by allowing static to dissipate at a safe rate without wearing off or losing resistivity. These coatings are made of a proprietary blend of electro-active polymers which allows the coating to be inherently dissipative regardless of ambient relative humidity. Intended for indoor use, the Staticide® ESD Safety Shield is simple to use since it is a water-based one-part system.

ACL's complete line of high purity solvents are the finest, most effective products made for the critical cleaning and degreasing of electronics, electrical assemblies and sensitive components. Each cleaning agent possesses unique properties suited to specific applications – from precision cleaning of solvent sensitive components to degreasing of electrical and electronic equipment.These high purity formulations remove environmental contaminants and protect contacts from corrosion and frictional wear. Contact cleaners restore electrical continuity to all electronic and electrical contacts by penetrating and removing insulating oil and grease, conductive carbon soil, and insulative oxides from contact surfaces. Most aerosols can be sprayed in any direction.

ACL, Inc.’s quality management system first achieved ISO certification in 1995. The requirements of the International Standards Organization have provided us an internal and external means of assessing our quality standards. Our strong commitment to quality allows us to provide effective solutions for static control problems around the world. Our current quality management system is ISO 9001:2015 certified.

ACL Staticide is committed to customer satisfaction. In the effort to help customers properly manage and use our products, we have listed the Safety Data Sheet on the individual product page.

For regulatory declarations such as REACH, RoHS, and Conflict Minerals, please send requests to info@aclstaticide.com.

For Certificates of Conformance, send requests toorders@aclstaticide.com. Include product number and lot number.

![]()

The unique CALIPRI principle is a development of laser light section technology from non-contact demension and profile measurements.

The systems in the CALIPRI C1X family measure gap and edge profile patterns without any extrapolation. Real data and color-coded gap width and flush offset provide a reliable basis for decision-making. Numerous patterns for measurement specifications and different model variants enable the cross-process application of a single technology.

The CALIPRI optical profile measurement device is suitable for profile measurements of individual components or for inspecting the dimensional accuracy of the complete unit. Compared to the sampling methods used in conventional measuring systems, the non-contact method delivers significantly more accurate and, therefore, reproducible measurement results.

CALIPRI non-contact profile measurement devices meet the demands of the railway industry with a reproducible and simple measurement method for the complete wheel-rail-system. Whether you are working with wheels, brakes, rails or switches – we have the right solution for any measurement task.

Forget about conventional approaches: In the future, carry out random sample measurements without delay using the portable profile measurement device CALIPRI RCX and, without an additional measuring system, evaluate cross sections and defects in one step with OSIRIS inspection systems. Both systems are based on non-contact measurement technology and obtain highly accurate measurement results.

The "Defects" CALIPRI C4X module helps users distinguish between critical and non-critical surface defects. Flat spots and spalling are evaluated with the non-contact measurement device, which is based on laser light section technology. An acoustic guide helps the user to position the measurement device. During the measurement operation itself, the sensor is simply aimed at the defect – there is no need to apply or precisely plot it. If there is a signal, it is a critical defect and the width and depth are calculated. After the measurement, the width and depth of the defect are shown on the sensor and the tablet PC and are automatically compared to the limit values entered.

Passing the €10 million barrier as early as the third quarter and winning the Fast Forward Award for the second time – NEXTSENSE reports economic successes for its 10th anniversary and has once again been given an award by the Styrian Business Promotion Agency (SFG).

As a professional manufacturer of scientific glassware, DIMA GLASS offer an extensive line of laboratory glassware supplies for the needs of scientific community. Our lab-glass features low expansion rate, high hardness and high softening point, resists heating and boiling in laboratories, and is suitable for a wide variety of standard experimentation procedures.

Dikma has over 15 years of R&D experience in chromatographic columns which have been widely used by pharmaceutical manufacturers.

With the growth of contamination generated from agricultural and industrial production, it causes a threat to the enviroment including drinking water, atmosphere and soil. The chemists have always seeked out the effective analytical methods to detect and identify chemical contaminants. Dikma provides innovative products and application solutions according to government regulations and industry standards, for air and water quality monitoring, gas detection.

Food samples exhibit a challenge to analytical chemists to determine pesticide residues to meet food safety regulations in USA and EU. Therefore, more careful sample preparation is needed to successfully identify and quantify these compounds in food.

The measurement of permanent gases, light hydrocarbons, sulfur compouds etc. in petrochemicals is important to petrochemical industry. Dikma offers a full range of products to measure these basic parameters.

Endeavorsil,UPLC,Natural Amino Acids,Aspartate,Glutamate,Serine,Glycine,Histidine

,Arginine,Threonine,Alanine,Proline,Tyrosine,Valin

e,Methionine,Cystine, Isoleucine Ile,Leucine,Norleucine,Phenylalanine,Tryptophan,

Lysine.

As a professional manufacturer of scientific glassware, DIMA GLASS offer an extensive line of laboratory glassware supplies for the needs of scientific community.

![]()

At INO, we specialize in developing solutions designed to make businesses more competitive, no matter what their size or area of activity. From consultation to production, we offer fast lead times and share the risks associated with technology development.

INO’s high power and high speed 3D profilers are designed to measure surfaces several meters wide with unprecedented accuracy in full sunlight. To this end, INO develops a series of dedicated software and hardware tools. Features are offered “à la carte” to speed up the product development cycle and deliver performance.

Lidar (light detection and ranging) is the leading optical technology for measuring distances, from a few meters to several kilometers. Like radar, it measures the travel time of light backscattered or reflected by a target. However, lidar makes it possible to determine distances and map its environment with greater precision.

INO’s industrial fiber laser platform allows users to select arbitrarily shaped pulse waveforms with durations ranging from 1 ns to over 1 µs to address a wide variety of laser materials processes. The energy deposition rate at the workpiece may be further controlled by regulating the temporal pulse shape, using either pulse-on-demand or pulse bursts, thanks to a proprietary MOPA system architecture featuring synchronous pumping. Pulse energy up to the mJ level and peak power in excess of 50 kW are readily achieved with outstanding pulse-to-pulse stability for consistent and precise results.

INO has developed a novel fiber optic chemical sensor technology based on ion-selective membranes. This sensor relies on the membrane’s absorption spectrum, which depends on the concentration of a target ion. The membrane is used as the cladding when deposited on a multimode fiber, which guides the signal. The uniqueness of this technology comes from the fact that the concentration of ions in the solution is monitored via evanescent wave spectroscopy. This configuration allows concentration measurements in colored or even opaque solutions, since the light propagating in the core only interrogates the membrane and never “sees” the medium under testing. Moreover, the membrane composition can be adjusted to detect different ions.

INO offers a complete range of MEMS/MOEMS foundry services. Whether you need a very specific service or a fully-integrated MEMS creation process, we have the resources and expertise to help you reach your goals and deliver results. Our state-of the-art MEMS foundry clean room facility is perfectly adapted to the processing of 6″ and 8″ silicon substrates.

Packaging accounts for a gigantic part of silicon photonics devices’ overall cost. Thanks to more than 20 years of experience in multiple packaging applications, INO can assume this critical challenge. We build custom silicon photonics packages that will meet your specifications.