Automovite / Railway / Steel / Aerospace

The systems in the CALIPRI C1X family measure gap and edge profile patterns without any extrapolation. Real data and color-coded gap width and flush offset provide a reliable basis for decision-making. Numerous patterns for measurement specifications and different model variants enable the cross-process application of a single technology. Download DATA SHEET-C10

The systems in the CALIPRI C1X family measure gap and edge profile patterns without any extrapolation. Real data and color-coded gap width and flush offset provide a reliable basis for decision-making. Numerous patterns for measurement specifications and different model variants enable the cross-process application of a single technology. Download DATA SHEET-C10

Calipri C10-Automotive Basic Bundle

Calipri C10-Automotive Basic Bundle The CALIPRI technology is suitable for both fully automatic inline use and manual spot checks at audit stations. Depending on the measurement task, different system versions are available.

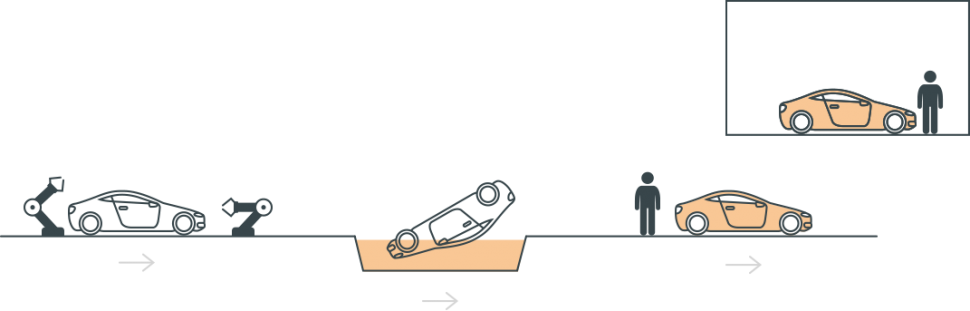

The CALIPRI technology is suitable for both fully automatic inline use and manual spot checks at audit stations. Depending on the measurement task, different system versions are available.

IN-LINE GAP MEASUREMENT ON THE PRODUCTION LINE

IN-LINE GAP MEASUREMENT ON THE PRODUCTION LINE Fully or semi-automatic stationary systems can measure directly inline, based on pre-defined and PLC-controlled measurement plans – extremely accurately and in a matter of seconds.

Fully or semi-automatic stationary systems can measure directly inline, based on pre-defined and PLC-controlled measurement plans – extremely accurately and in a matter of seconds.

We offer application-related systems for body shops, assembly and timed production lines. CALIPRI C11 and CALIPRI C15 are robust, semi-automatic gap measuring systems with low training requirements. Or do you prefer fully automatic systems? The CALIPRI C12 series – suitable for HRC – chooses measurement plans via PLC and, in a matter of seconds, carries out measurement operations using a robotic arm. All measurement devices possess the same mathematical measurement specifications. Both systems clearly display measured values and gap profiles on monitors and show exceeded limits with color-coded overlays. Data is exported automatically as CSV, XML or, on request, using your own interface.

The CALIPRI technology is suitable for both fully automatic inline use and manual spot checks at audit stations. Depending on the measurement task, different system versions are available.

The CALIPRI technology is suitable for both fully automatic inline use and manual spot checks at audit stations. Depending on the measurement task, different system versions are available.